Simulation Quartz Glass Sagging

Figure 1: Animation quartz glass sagging

The simulation of quartz glass sagging can perfectly be performed with our CFD software NOGRID points. Fused Silica (SiO2) is a synthetic molten, amorphous quartz glass. Quartz glass has an extraordinarily high optical transmissivity for ultraviolet light. Due to its low coefficient of thermal expansion, quartz glass can withstand very high operating temperatures. The very good UV-light transparency of quartz glass cannot be outperformed by any other industrial glass material. Quartz glass components and fused silica optics are made of large silica glass blocks, called quartz glass "boules". This raw fused quartz glass material can be sawn, ground, polished and shaped according to customers specifications.

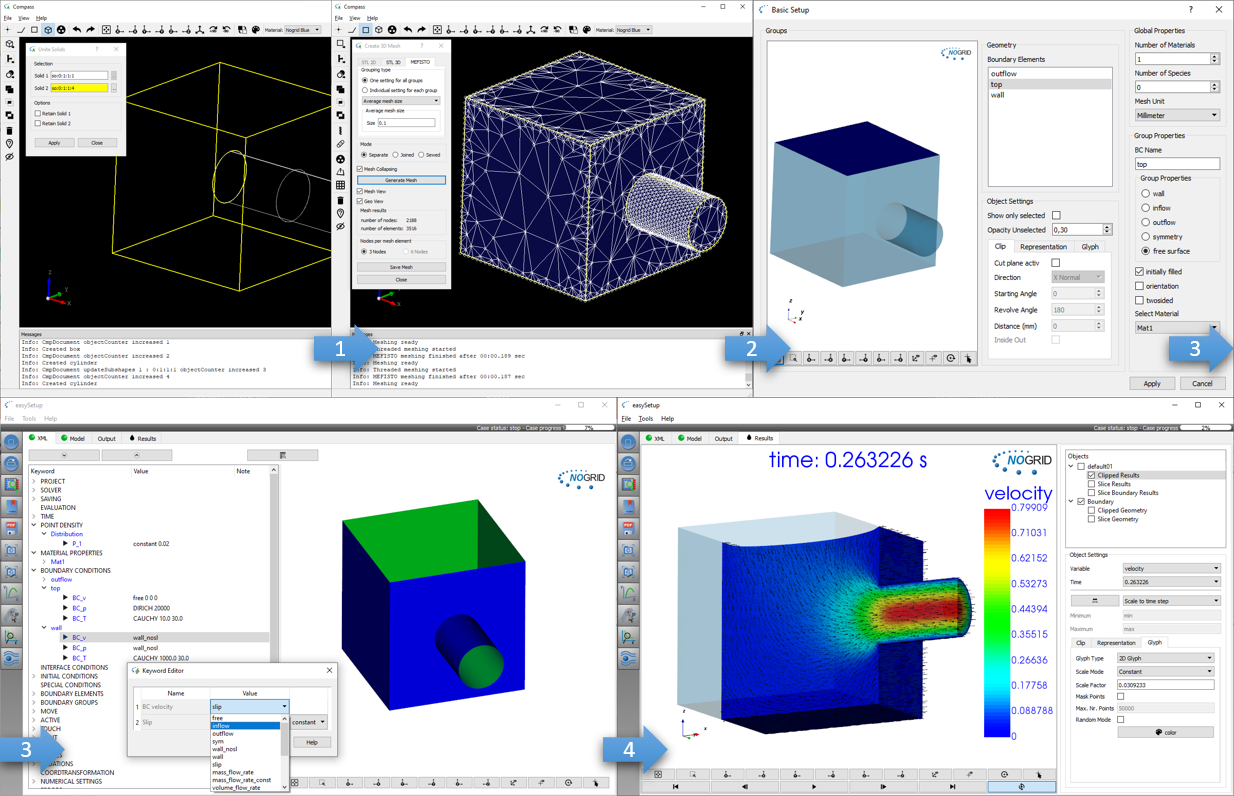

Here we present a simulation, computed by our meshless CFD software NOGRID points, where a quartz glass cylinder is formed in an oven under its dead weight.

Quartz glass is most commonly heated in an oven and 'sagging' it over a form or into a mold. The glass is heated up slowly to avoid thermal shock. Approximately at the sagging temperature the quartz glass will begin to soften and appear glossy. Depending on the required process time sagging occurs at 100 °C to 300 °C above the sagging temperature. Once the quartz glass has sagged to the final state or the quartz glass has achieved the desired form the heat is quickly vented and the temperature is reduced to prevent further movement of the quartz glass and then it is stabilized at its respective annealing temperature and annealed.

It is also possible to simulate a forming process using different tools to accelerate the forming time.

NOGRID unites abilities to handle free surface flow and moving parts in the domain and allows the simulation of any conceivable geometry and operation modes such as

- computation is in full 3D solving complete Navier-Stokes-Equations

- easy and intuitive setup

- free definable material properties by equations or curves also for non-Newtonian fluids

- evaluation of chemical reactions and corresponding heat source terms

- open or closed domains including inflow and outflow areas (non-batch mode)

- moving of parts

Nogrid's strengths

Easy and fast modelling: Build geometry, mesh boundary, setup the case and start computation

What is CFD from NOGRID?

CFD solves the fundamental equations that define the fluid flow process. With CFD software from NOGRID every engineer makes better decisions by predicting, analyzing and controlling fluid flow, heat and mass transfer or chemical reaction. By using NOGRID software for flow modeling you receive information on essential flow characteristics as for example flow distribution. Using it additional to testing and experimentation NOGRID software helps to improve the evaluation of your design – resulting in better construction and operation parameters, increasing planning security and money savings due to faster time to the marketplace for your product or process.

Choose NOGRID

With NOGRID, you choose professional CFD software and services – our aim is helping you to be successful. When you decide to work with NOGRID you choose close cooperation with a dynamic, flat hierarchies-organization. Short information channels result in quick and accurate professional support and service. Our team consists of highly qualified employees, who are experts in fields such as numerical simulation or computational fluid dynamics. Based on our know-how, we are pleased to offer the following services, responding to your individual requirements:

TRAINING

In our two-days training courses you will learn, how to use NOGRID CFD software efficiently. Our technical support team will teach you how to handle and solve different cases.

For more details please refer to Training Courses →

Technical Support

We offer full professional support from the minute you start using our software, by telephone or by email. Contact us, when ever needed.

For more details please refer to Software Support →

Service

Lack of time or resources and other constraints often make outsourcing an attractive solution. We help you with your flow modeling needs. Based on our engineering expertise in this field we offer individual numerical simulation services matching the unique needs of your organization.

For more details please refer to Simulation Services →