NOGRID pointsBlow - 3D Simulation Software for Container Glass Forming

NOGRID pointsBlow 3D simulation software for container glass forming is the perfect tool for improving your glass containers. The production of glass bottles often requires many costly trials on the production line until the requested quality is achieved. By simulation of the container forming process, you can compare different variants of your containers and get a solid basis for every optimization, which leads to cost reductions and time savings. The glass simulation software NOGRID pointsBlow was developed and designed especially for the glass container industry. With this CFD (Computational Fluid Dynamics) glass software program the container forming process can be computed in full 3D in a practicable time. For glassmakers this software is an indispensable tool to support glass design, production process, and quality control of glass containers.

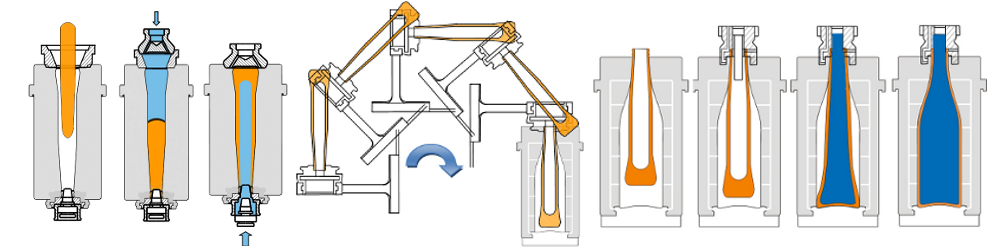

Figure 1: Result view of some selected time steps performed with NOGRID pointsBlow simulation software for container glass computed in full 3D

Process types in NOGRID pointsBlow

The following kinds of container glass forming processes can be simulated in full 3D or in 2D-axisymmetric:

- BB (Blow and Blow),

- PB (Press and Blow or Wide Mouth PB)

- NNPB (Narrow Neck Press and Blow)

- PB tableware (Press and Blow for the tableware industry)

Figure 2: Blow and Blow (BB) process steps

Simulation for every serious imaginable bottle design

As in reality, the simulation starts with gob loading and ends at take out. All process steps are integrated in one simulation model and all walls are activated and deactivated at the corresponding time step given by the IS machine time data. As shown in figure 2 the shape of the bottle can be any 3D shape. Also bottles with a handle or perfume bottles can be computed. Thus, there are no limits to the glass bottle design and the user can test and evaluate a container design without restrictions.

In the past many glass container designs were computed and compared to real bottles with perfect results. The weights of the computed bottles can be any weight - there is no limit. The computation time depends on gob weight and is in the range of minutes for 2D computations and in the range of hours for 3D computations.

Figure 3: NOGRID pointsBlow can compute all kinds of containers: 3D, 3D-clip and 2D-axis-symmetric

Results

In order to analyze the results the glass simulation software NOGRID pointsBlow computes, beside velocity, pressure and temperature, the container thickness at each time step by solving an additional differential equation. The user can select the thickness distribution like an usual variable such as, for example, the temperature (see figure on the right side). The XY-plot displayed shows the thickness distribution over the height of the bottle. In addition, the user can select certain single points within the glass volume and the software probes and displays all variables at that position.

Input data for NOGRID pointsBlow

NOGRID pointsBlow needs input data before starting the simulation of a container: Geometrical data, initial and boundary conditions, material data, and process data.

The first question for the user who starts working with NOGRID pointsBlow is how to build the geometry, the shape of the blank mold, the shape of the final mold, the plug or plunger shape and of course the geometry of the initial glass gob immediately before loading. The gob geometry is freely selectable within the GUI. Since all companies use individual CAD systems for modeling molds and other parts, NOGRID pointsBlow can import all required shapes using the well-known STEP interface.

This means the user can simply extract the shapes required into one CAD file and export this file to STEP format; most CAD packages support exporting to STEP format. If all material properties and process properties are given, the user can start the computation immediately. Because NOGRID pointsBlow is a software based on a meshfree code, no meshing is required and the points within the initial gob are filled automatically.

Figure 4: 3D thickness view, xy-plot and point probing in NOGRID pointsBlow

Figure 5: Animation of a computed container in full 3D with a rectangular shape

Benefits of container glass simulation software

NOGRID pointsBlow computes the forming process using all IS machine time data including pressure data, plunger movement, and heat transfer data. The plunger movement can be driven by force or can be given by time position curve. It is clear that IS time machine settings can improve or worsen the quality of thickness distribution, so NOGRID software helps with the following:

- Finding the optimal blank mold shape

- Reducing the number of mold design tests

- Finding the best IS time machine data

- Reducing the number of trials in production

- Finding the lowest possible container weight

Last but not least NOGRID pointsBlow helps to understand the origins of glass defects in the container. Therefore, simulation helps to understand how the forming process is working in detail, which is the basis for all improvements.

Save money by using container glass simulation software

NOGRID pointsBlow glass simulation software allows all main glass container forming processes being simulated in full 3D and in a practicable time. The graphical user interface (GUI) is designed especially for the glass container industry and all modeling and simulation steps are easy to understand and perform.

By using the software, the number of mold and production design trials can be significantly reduced and the license investment costs can be amortized after the first new glass bottle design.

NOGRID pointsBlow is unique and unmatched on the market: any software except NOGRID pointsBlow can simulate the glass forming process of container glass for the forming processes Blow Blow (BB), Press and Blow (PB), Narrow Neck Press and Blow (NNPB) and PB for tableware in full 3D and in feasible computation time.

Nogrid pointsBlow product box

As a container glass manufacturer you should not miss the opportunity to test our software. You won't find any other software worldwide for the 3D simulation of the container glass forming process that can generate solid solutions in a very short time. Even complicated forms of glass containers, such as bottles with handles, can be simulated with the container glass simulation software NOGRID pointsBlow.

Don't miss your chance and simulate the container glass forming process in the most professional way. You'll be more effective while saving time and resources with NOGRID pointsBlow software. You will be convinced and inspired if you decide to test our software. Please contact us for a trial version.